Bradley, S19314PZ, Halo Combination Drench Shower and Eyewash, Plastic Bowl and Showerhead, With Spray Hose, European and Australian

Features:

- Spintec Showerhead provides the most consistent distribution of water from a drench shower, improving user washdown

- Galvanized steel protected with Bradtect safety yellow coating

- Universal identification sign and inspection tag included

- Includes 8" hand-held drench hose for face and body rinse

- Drench Shower exceeds minimum water flow of 20 GPM at 30 PSI

- Eyewash exceeds minimum water flow of 0.4 GPM at 30 PSI

- BSPP thread

Units save space and fit easily into any work environment. The shower valve operates quickly by a pull rod with a triangular handle. The shower provides a superior washdown with a more even spray pattern. Operated by an ergonomic, highly visible push handle, provides effective wash down coverage and spray pattern. Integral strainer reduces debris in the water and also prevents clogging.

Pipe and Fittings

Piping to 1-1/4" NPT (BSPP) water supply inlet on the unit. Piping to 1-1/4" NPT (BSPP) drain outlet for eyewash.

Ball Valve

1" shower ball valve and 1/2" stay-open wash valve supplied with stainless steel pull rod and handle.

SpinTec Showerhead

SpinTec drench showerhead features integral 22 GPM (83.3 L) flow control (exceeds minimum water flow of 20 GPM (75.7L) at 30 PSI (2.0 bar)), conserving water and helping to accurately size your tepid water system.

Eyewash

The Halo eyewash system offers a high-performance rinsing platform that provides rapid relief to an individual's eyes that have been injured by chemicals or particulate. The eyewash includes an integral 5.1 GPM (19.2 L) flow control, providing water at a safe velocity while maintaining its effectiveness (exceeds minimum water flow of 0.4 GPM (1.5 L) at 30 PSI (2.0 bar)). The eyewash is protected by flip open dust covers that open when the product is activated or by a full bowl dust cover that activates the unit when it is opened. Safe, steady water flow under varying water supply conditions from 30-90 PSI (2.0-6.1 bar) is assured by integral flow control in the spray head assembly.

Backflow Prevention

Series N9 dual-check backflow preventer has a chrome-nickel plated brass body and includes an atmospheric vent for continuous pressure applications. The check valve comes with a 3/8" female dual NPT female inlet and outlet connections. It can sustain a maximum pressure of 125 PSI (8.6 bars). The check valve is certified to CSA B64.8. Series 9D dual-check backflow preventer with intermediate atmospheric vent can be used under continuous pressure. The primary check valve uses a rubber disc seating adjacent to a mating rubber part to ensure tight closing. A second check valve employs a rubber disc-to-metal seating.

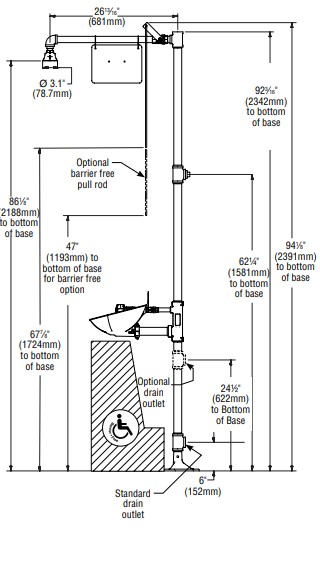

Dimensions: