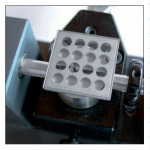

Tool presetters are specialized devices utilized for precision measuring of mill operating parts (cutters, drills, and more). Knowing the exact size of tools is crucial when manufacturing parts and regular measuring tools do not provide enough accuracy. Gage blocks may be used, however, assembling them into strips of required lengths takes up a lot of time. CNC-operated mills can utilize tool presetters - electronic measuring devices that provide extremely accurate parameters of a tool and save these parameters for later use in manufacturing. Measuring systems are complex set-ups that contain special stands for the manufactured part and a set of sensors/measuring devices, which record all necessary parameters and compare them with requirements. This system can be connected to a computer and provide data for analysis. These appliances are used when evaluating parts and checking them for defects or damage.