- Show results for

- Share

What is a Tachometer and How Does it Work?

Resource Description

Table of Contents

Introduction

What is a Tachometer?

A tachometer (also known as tach, revolution-counter, rev-counter) is a device that is used to measure the rotation speed of a shaft or disk in a motor or other machine. A tachometer measures the revolutions per minute (RPM) of a moving object.

A tachometer will help you figure out whether the machine works too slow or too fast. You can ensure that you don’t exceed the maximum speed so the machine is not damaged.

Handheld tachometers are widely used in the industrial sector. They are irreplaceable when it comes to the maintenance and calibration of machines with moving parts. Applications include measuring the speed of motors, centrifuges, pumps, the list goes on.

Tachometers are used in various industrial facilities such as power plants, chemical plants, automotive plants, etc. These devices are also used in material handling, food and beverage, and many other industries.

Types of tachometers

There are various types of tachometers.

Contact, non-contact, contact/non-contact tachometers

Based on the fact of making or not making a contact with the component of the machine that is being measured, there are the following types of tachometers.

Contact tachometer

As the name implies, a contact tachometer requires a contact with a rotating object for the measurement of its RPM.

What are the elements of a contact tachometer?

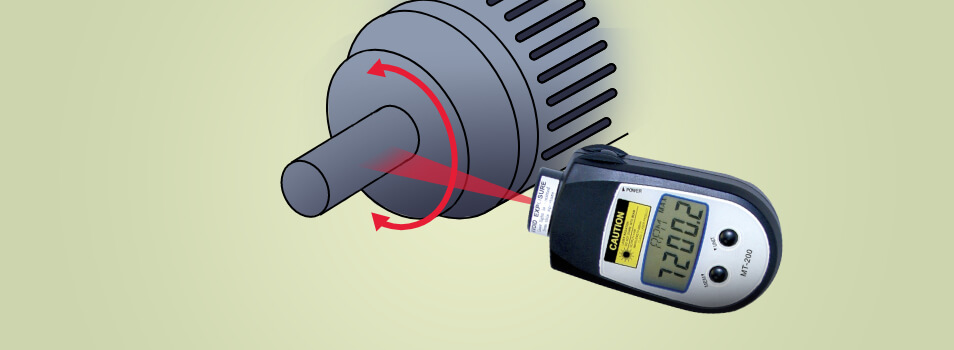

Look at the image below. You can see an example of one variant of a contact tachometer. Depending on the manufacturer, the components may vary from model to model.

A contact tachometer has a contact measuring device which is a key part of the whole tachometer. On top of the tachometer you can see a shaft on which an RPM adapter or a surface speed wheel is attached. These are the elements that contact the object the speed of which you want to measure. With the help of the function switch, you can switch between the units of measurement. The memory call button is used to show the last reading. The readings are shown on the display. In this example, the measure button(to start the measurement) is placed on the side of the device, however, it can be on the front of your tachometer. The placement of this button varies depending on the model and manufacturer. As it is a portable handheld device, there is a battery section with a battery cover.

How does a contact tachometer work?

The shaft of the rotating component is coupled to the shaft of your tachometer by friction. The shaft of the tachometer is going to rotate at the same speed as the rotating component you are measuring.

A freely spinning wheel of the tachometer is brought in contact with a rotating shaft or disk. The shaft drives the wheel and, as a result, the pulses are generated. These pulses are read by a tachometer and measured in revolutions per minute (RPM).

In addition, with a contact tachometer, you can measure linear speed.

How to use a contact tachometer?

In order to measure, for instance,theconveyor belt speed, you need a contact tachometer with a wheel attachment. The measuring process is easy, just place the wheel against the conveyor belt and the wheel of your tachometer will rotate at the same rate. Your device will show the results of the linear speed measurement on the display. The calculations are made based on the rotational rate and a fixed diameter of the wheel of your tachometer.

Non-contact tachometer

A non-contact tachometer, as you may have already guessed, doesn’t require any physical contact with the rotating shaft. Instead, it utilizes a laser, IR light or other light sources for the measurements. Digital tachometers with optical sensors are known as optical tachometers. Non-contact digital tachometers are perfect for use in hard-to-reach areas.

A non-contact tachometer is visually similar to a contact tachometer except for one thing. On top of the device (as a rule, the location may be different), instead of a shaft, there is a light beam irradiation port.

Laser tachometer

A laser tachometer is a non-contact device that utilizes laser, which is pointed at the rotating object for the measurement of RPM. There are various detecting distances and they vary depending on the model, typically, it is within 78 inches (or 2 meters).

How does a laser tachometer work?

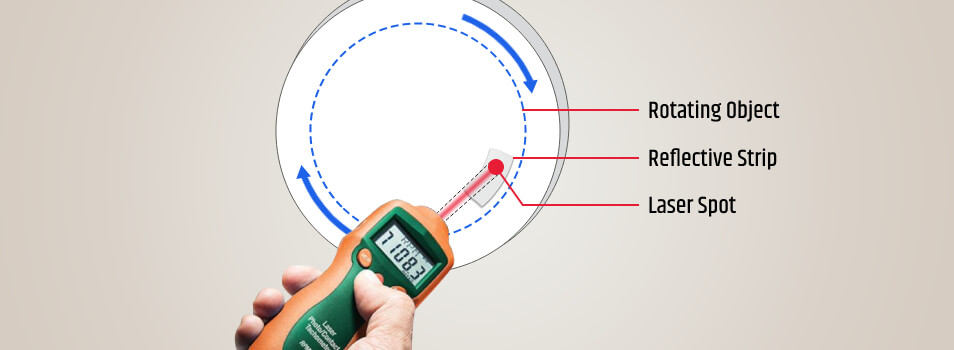

First things first, a piece of a reflective material should be affixed to the rotating component (see the picture below).

Now let’s move on to the device.

A contactless laser tachometer sends out a beam of laser light. This beam is directed towards a reflective strip (tape) on the rotating object. The laser spot should be seen on the reflective tape. When the light beam strikes this tape, it is reflected back to the light sensor in the tachometer. The device will count the number of times when the reflected signal is received. As a result, you will get the reading in revolutions per minute.

Strobe tachometer

What is a strobe tachometer and how does it work?

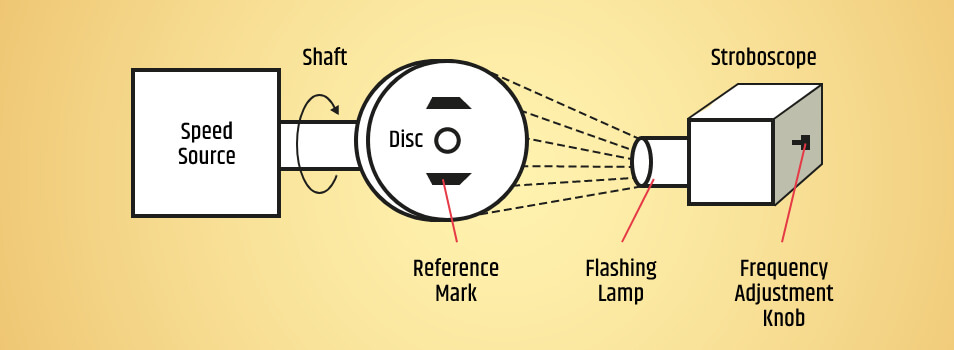

A strobe tachometer (or a stroboscope) is a device that measures the rotation speed of an object using the stroboscopic method. This device produces regular flashes of light. If the frequency of these flashes is correct, then the rotating object will be illuminated during each flash of light. In this case, the object will appear to be stationary. Thanks to this stop-motion effect, it is possible to study rotating, oscillating, or vibrating objects.

Take a look at the diagram below. It explains the process of measurement of the rotational speed of the object using the stroboscopic method.

The speed source of the machine rotates the shaft and the disk is rotating as well. The flashing lamp emits the light. The frequency of the flashes of light is adjusted using a frequency adjustment knob until the reference marks on the disk appear to be stationary. Note that the more out the phase the light of your stroboscope is with the test frequency, the faster the motion will appear. In case the motion appears too fast or too slow, identifying changes in the device and detecting failures can be a hard task.

Stroboscopes are used for the testing of fans, pumps, motors, and more. Applications include general maintenance, quality control, etc.

Contact/Non-contact tachometer

Maybe you don’t like the limitations of a contact or non-contact tachometer. Or you need both but you don’t want to buy and carry around two separate devices. In this case, a contact/non contact tachometer is the best option for you. It’s a 1-in-2 device, its great advantage is versatility. It is a combination of a contact and non-contact tachometers. Such devices feature both a shaft to attach the adapter and a light beam irradiation port, which is very convenient.

Time & frequency measuring tachometers

A time measuring tachometer calculates the speed of the object by measuring the time interval between incoming pulses. This type of tachometers is perfect for the measurement of low speed with high accuracy.

A frequency measuring tachometer calculates the speed of the object by measuring the frequency of the pulses.

Conclusion

Now you know what a tachometer is, what types of tachometers there are and their working principle. If you are in search of a new tachometer, choose from a wide range of models on our website. In addition, for a contact tachometer, you need to make sure that you use the right accessories for the exact model you have. In addition to top-quality tachometers, on our website, you can also get cones, measuring wheels, and more.