- Show results for

- Share

How to Use Refractometers

Resource Description

A Refractometer is a laboratory or field device for the measurement of an index of refraction (refractometry).

There are four main types of refractometers: traditional handheld refractometers, digital handheld, laboratory or Abbe refractometers, and in-line process refractometers.

The range of spheres of a given instrument’s usage is rather wide:

- In veterinary medicine, a refractometer is used to measure the total plasma protein in a blood sample and urine specific gravity.

- In drug diagnostics, a refractometer is used to measure the specific gravity of human urine.

- In gemmology, the gemstone refractometer is one of the fundamental pieces of equipment used in a gemological laboratory.

- In marine aquarium keeping, a refractometer is used to measure the salinity and specific gravity of the water.

- In Automobile Industry, a refractometer is used to measure the coolant concentration and pH of the Coolant Oils for the CNC Machining Process.

- In homebrewing, a refractometer is used to measure the specific gravity before fermentation to determine the amount of fermentable sugars that will potentially be converted to alcohol.

For most of the spheres, a proper refractometer is required.

What you’re going to find in this article is a how-to-use discussion on the example of handheld refractometers, dealing with an often referred to as “soluble solids” or “sugar” testing, which is important in testing fruits (maturity evaluation), quality of fruit juices, energy drinks, jam, marmalade, starch syrup, liquid sugar, honey, as well as a brewery.

Choosing and Using a Handheld Refractometer

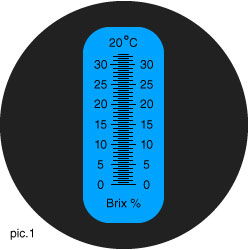

There are two types of handheld refractometers: analog and digital. They work on the principle that light entering a prism has a unique characteristic. That characteristic is represented by a value on a scale in units known as ºBrix. When light enters a dry prism, the field of view in an analog refractometer remains blue (pic. 1). In a digital refractometer, an error message would appear. Both are indications that the light is not being interfered with as it passes through the prism.

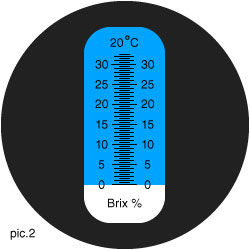

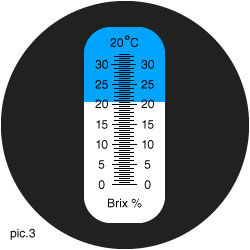

Pure water placed on the refractometer should result in a reading of zero (pic. 2). A solution containing sucrose (table sugar or fruit juice) placed on the prism surface will change the direction of the light significantly. Depending on the amount of sucrose in solution, the ºBrix will range from 0 to 25+ for most agricultural crops. In Pic. 3, an analog refractometer displays a reading from a sample that is 21 ºBrix.

Handheld analog refractometers are convenient because they do not require an energy source. However,

they may not be accurate if used outside the specified temperature range. Older refractometers will

give accurate readings only when the temperature is at 68ºF (20ºC). Both the refractometer

and the sample must be at this temperature. When temperatures are above or below optimal, a

corrections table is needed to determine actual ºBrix. Readings can be as much as

0.89

ºBrix lower when the temperature is 50ºF (10ºC) if a correction is not made. If

samples are being evaluated at temperatures close to room temperature, the difference is probably of

little practical significance. However, if evaluations are being made outdoors in the heat, then it

is important to adjust the readings by a given factor provided by the manufacturer. Newer

refractometers compensate for fluctuations in temperature, but are still only accurate within a

specified range of temperatures. A range between 68-86ºF (20- 30ºC) is the most common for

temperature compensated (TC) or automatic temperature compensation (ATC) refractometers.

Refractometers with larger ATC ranges are available, but are more expensive.

Readings can be as much as

0.89

ºBrix lower when the temperature is 50ºF (10ºC) if a correction is not made. If

samples are being evaluated at temperatures close to room temperature, the difference is probably of

little practical significance. However, if evaluations are being made outdoors in the heat, then it

is important to adjust the readings by a given factor provided by the manufacturer. Newer

refractometers compensate for fluctuations in temperature, but are still only accurate within a

specified range of temperatures. A range between 68-86ºF (20- 30ºC) is the most common for

temperature compensated (TC) or automatic temperature compensation (ATC) refractometers.

Refractometers with larger ATC ranges are available, but are more expensive.

Samples evaluated in summer day will result in inaccurate readings. If using a non-ATC refractometer, as the temperature increases, accuracy of the reading will be compromised. Accuracy improves when samples are taken back to a lab or office for processing at room temperature. Note that testing samples during hot weather can give a “false” increase in actual ºBrix. Deciding whether the difference is significant will depend on how close you are to the critical range for decision-making.

If using an analog refractometer, whenever possible, all samples should be read by one person, since readings are somewhat subjective.

Handheld digital refractometers are convenient, often have ATC, and readings are less subjective. Batteries are needed and should be replaced from time to time. Juice samples are deposited into a well that allows a light-emitting diode (LED) to reflect light through the prism. A liquid crystal display (LCD) screen displays the ºBrix reading in seconds. As quickly as you can clean the well with water and dry it, the next sample can be tested. In addition to the hot sun affecting digital refractometers when outside of the optimal ATC range, bright light can interfere with accuracy. Shading the sample well will eliminate the interference from sunlight.

Whichever style of refractometer you choose, it is important to identify your objective and determine what options are important to you. Analog refractometers are popular with growers because they are easy to use and relatively inexpensive (approximately $100-200). A digital refractometer will usually result in more rapid readings and more accurate data (approximately $300).

Calibration

Calibrating the refractometer is the first step in evaluating the sugar content of fruit. It is an easy but often neglected task. Calibration verifies the zero baseline reading, ensuring that subsequent fruit juice sample readings are accurate. Fruit harvest decisions based on inaccurate sugar readings can impact quality, storage durability, and sales. Refractometers should be calibrated at the beginning of each use and, depending on how many samples are being measured, periodically throughout the sampling process.

Proper calibration requires a pure water source and testing solutions of known sucrose concentration. Water allows the user to “zero” the refractometer so fruit juices can be correctly measured. An ideal water source is deionized (DI) or distilled water that has been filtered to remove ions such as sodium, calcium, iron, and other impurities. In the past, both types of water were available at grocery stores, but are now difficult to find due to production cost. More common now are many brands of bottled drinking water, which have been filtered using reverse osmosis to remove impurities. Test solutions are needed to calibrate your refractometer. Kits that include solutions with known ºBrix values can be purchased from refractometer manufacturers but can be expensive.

Steps for Calibration

- Inspect the refractometer prism for scratches, chips, separations, or other aberrations that may interfere with proper readings. If dusty, rinse with water and wipe with a clean, soft, lint-free cloth.

- Note the temperature at the time of readings. Most ATC refractometers operate properly in the 68-86ºF range. A laboratory or office at room temperature should be used if outside temperatures exceed the manufacturer's recommended temperature range.

- Place a few drops of pure water on the prism surface. If it is an analog refractometer, close the cover. If bubbles form, gently pressing the cover will remove the bubbles and help disperse the water over the entire surface. For digital refractometers, make sure that bubbles in the well are eliminated prior to taking a reading.

- Hold the refractometer up to natural light or an incandescent bulb to obtain the reading. Looking into the eyepiece, one should see a distinct separation between a blue and white section, often called a “contrast” line. If the contrast line is not directly at zero, then adjust by turning the screw on the top of the refractometer until it reads zero (pic. 2). Replace the plastic cap after adjusting the calibration screw to prevent water from entering the refractometer. You can adjust the focus by twisting the eyepiece until the scale can be seen clearly. Once the refractometer is calibrated to zero with pure water, dry the surfaces with a clean cloth. Digital refractometers should be calibrated by pressing the zero button with water in the well.

Maintenance

Refractometers are analytical instruments that must be properly maintained for accurate readings. Here are some simple tips to assure accurate readings from season to season and from use to use.

- Refractometers should not be exposed to wet environments. After each reading or before storing the refractometer, the prism should be thoroughly cleaned with water and dried.

- If the field of view in an analog refractometer becomes cloudy, it most likely has been immersed in water and can only be fixed by a professional technician. Exposing a digital refractometer to excess water may damage the internal electronics.

- Do not (!) evaluate solutions that the refractometer is not made for. If your goal is to read sugar samples, do not try to measure saline solutions. Doing so will compromise the instrument. Purchase a refractometer made for the solution you are interested in evaluating. Handle your refractometer with care. Dropping it can break, scratch, or displace the optics and/or prism.

- Store your refractometer in a location that has a constant temperature. Storing it in a location that has more than a 5ºF difference each day will severely compromise the optics and prism.