- Show results for

- Share

How To Cut Rebar?

Resource Description

Content:

Rebar also known as reinforcing bars are staples in construction and masonry. Rebar has plenty of advantages such as being durable and useful for supporting concrete by providing a solid structure.

Rebar may be applied alone or with the use of the steel mesh wire as reinforcement in concrete products. It is usually produced locally and from old cars and appliances. Several rebars are produced from 95% of recycled materials. Rebars made of steel are generally cut into very long lengths up to 60 feet.

Residential applications such as landscaping or concrete work generally apply #3 rebar, which measures ⅜ of an inch in diameter. Larger diameters of the rebar are generally applied in industrial or commercial applications as they require specific tools to cut them.

The most applied type of rebar by hobbyists is rebar #4, which is ½ inch in diameter. Such a size of the rebar may be cut with a hacksaw when larger rebars will need the other tool.

Preparation

There are several tips for safety preparation before you start cutting:

Step 1:

The first step involves measuring the rebar before cutting it. The rebar is commonly sold in a length of about 20 feet. If you won’t work with long pieces of rebar, you need to take accurate measurements before the cutting process. You may use a tape measure to mark the needed length of the cut.

Step 2:

You should take the proper safety precautions while cutting steel as rebar can be heavy and its ends may be sharp. When you work with it and apply a metal blade to cut the metal surface, it will produce sparks and metal shaving will fly in the air. That is why you use proper safety equipment and wear a safety mask or goggles and gloves to protect yourself from unwanted injuries.

Step 3:

Make sure that the workspace is spacious enough for the work with rebar. The length of rebars may vary from 8 to 60 feet (2.4 to 18.2 m). While working with the rebar in the open space it is ideal and clear of any obstructions. Make sure that the working surface is clear of any flammable components as rebar generates sparks while working with it.

Ways Of Cutting Rebar

Hacksaw

The hacksaw is the most basic and cheapest tool to cut the rebar. However, you will need a lot of patience and arm strength to cut this reinforcement steel. To apply the hacksaw you will need to measure the rebar and mark the point you need to cut. After that, you need to clamp the reinforcement steel for safety. Then, make cuts slowly on the marked points till you create a groove on it, and begin making long steady cuts until the rebar is cut off.

Popular Products

Angle Grinder

Angle grinders are available in various sizes, however, the most applied one for cutting rebar is 4 and 4.5 in. grinders. Users prefer them as they may provide fast and rough cuts. You may apply an angle grinder to cut rebar, angle irons, rusted bolts, and welding fences. The significant thing you should note about the angle grinder is that the device spins at the rate of 10.000 to 11.000 rpm (revolutions per minute) and can be dangerous.

Popular Products

Bolt Cutter

The power of the bolt cutter shouldn’t be underestimated. The tool is most commonly used to remove various padlocks and chains, but it is also effective in snapping rebar. The bolt cutter includes sharp blades and a metal cutting force of more than 400 lb. It may be compact and powerful simultaneously to keep you cutting rebar.

Popular Products

Jigsaw

A jigsaw is a portable tool for cutting rebar. You just need to press the trigger in the handle to apply it, cutting the rebar. This tool is suitable for cutting metal from 10mm to 30mm. The jigsaw has a metal base known as the shoe. You need to place the top of the shoe at the surface you need to cut, hold the device steady, and press gently. You may take breaks to oil the metal to prevent it from being damaged. When the blade seems to break, stop cutting immediately and move the tool away.

Popular Products

Miter Saw

You may also apply a miter saw to cut the rebar. This tool may cut the metal straight at a 90-degree angle or even at other angles. This device is suitable for cutting timber. The miter saw has similar functions to the chop saw and circular saw.

Popular Products

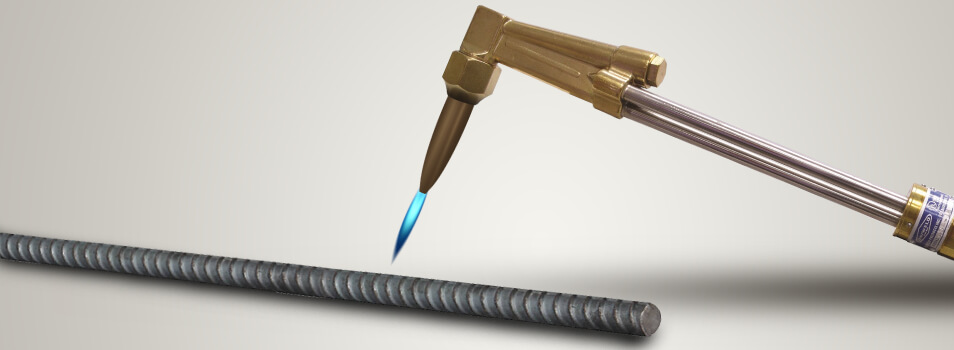

Torch

The torch cuts metal by heating it. The torch heats the part of the metal where it is required to cut and makes it pliable or soft. Don’t cut fast as it may lead to irregular results. You should note that the cutting torch may give the reinforcement steel a rounded or uneven cut section. Try to avoid applying plasma troches or oxyacetylene torches for large operations. The disadvantage of applying such touches is the creation of slag or wastage around the cut.

Popular Products

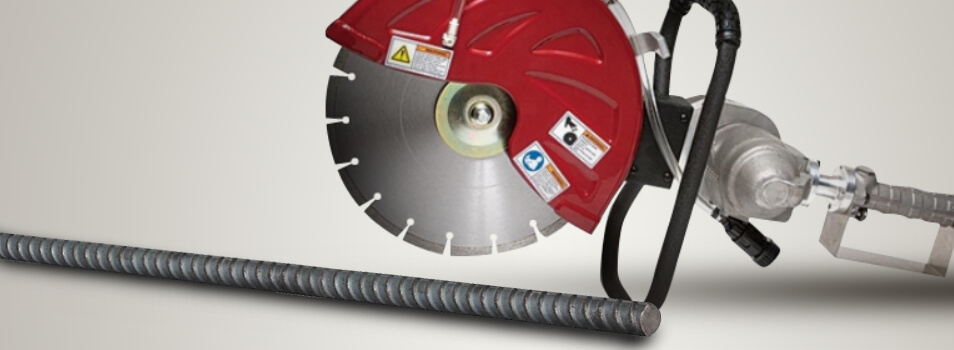

Chop Saw

A chop saw is a significant tool for the rebar cutting process. This tool is similar to the miter saw, but the only difference is its blade. It applies a large carbide blade. You need to adjust the speed of the tool to the required setting and cut through the rebar.

The chop saw is quite costly, but it is one of the ideal options for the rebar cutting process in large quantities due to the tool's big size. The completed cuts created by the chop saw are very clear and smooth. This tool creates a more precise and clear angle than the angled grinder does. The only drawback is that the tool makes a loud noise and it is not portable.

Popular Products

Rebar Cutter

A rebar cutter is one of the newest solutions for the rebar cutting process on the market. It is a portable tool that operates fast and smoothly. The device can cut up to #8 bar grade-60 in a few seconds. The tool also has a lock trigger switch for safety. The major benefit of the rebar cutter is that it doesn’t generate any sparks or flame.

Popular Products

Reciprocating Saw

The reinforcement steel can be also cut by the reciprocating saw, also known as the teeth saw. The method is to set the device in straight mode instead of oscillating mode. You should set the speed to slow to prevent the blade from being damaged. For thin metals, select the blade of 20 to 25 TPI (teeth per inch), and for medium thick metals choose 10 to 17 TPI and 7 to 9 TPI for thick metals. If you want to extend the term of the blade, use a carbide tooth blade. Applying the blade with a back tooth will provide better results.

Popular Products

Conclusion

We have mentioned different methods on how to cut the rebar. Several methods provide the best cutting results, while some are cheaper, handheld, or fast. However, you should note that safety is the top priority during work. Nevertheless, there are many factors that impact the proper cutting operation of the rebar:

The quality and the size of the reinforcement steel;

The tool you have selected for the work;

Budget;

Time;

Safety.