- Show results for

- Share

How To Clean Soldering Iron

Resource Description

The soldering iron should be cleaned regularly, due to the iron tips' contact with hot metal and they are sensitive to corroding or rusting. However, cleaning the iron soldering tip so often may lead to its damage over time. Providing appropriate cleaning methods regularly will allow you to achieve long-lasting iron conditions for years.

Why Is Cleaning Soldering Iron Crucial?

It is quite difficult to solder particles when the soldering iron tip is dirty. When you tin the soldering iron tip, the covering flattens out and the tip provides a better connection with a wider contact area that creates a more efficient heat path.

Proper tinning also provides longer life for the soldering iron tip. Most tips are made of a copper base material and plated with iron to be erosion-resistant. When the tip is oxidized, it is coated with a black or brown scale, which won’t be wet with solder, thus reducing the heat transmission. Such a tip condition is called burn-out. Burnt-out tips are generally discarded, so they should be cleaned properly and carefully.

Tools You Need To Clean The Soldering Iron appropriately

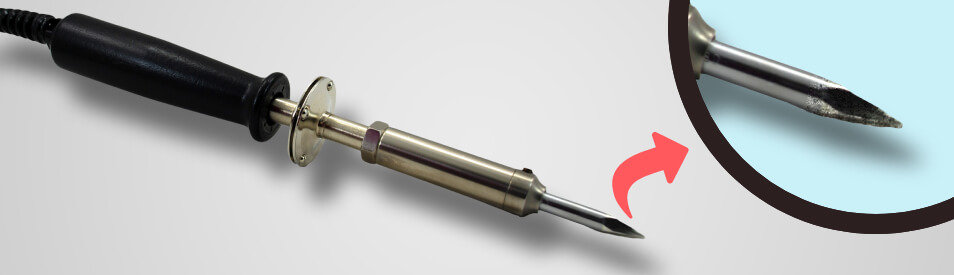

Soldering Iron

|

|

A soldering iron is a unique tool applied for soldering. It consists of a heated metal tip and an insulated handle. It provides solder softening, flowing it into the joint between two metal pieces to offer physical attachment of element to element, element to the board, or element to wire. |

||

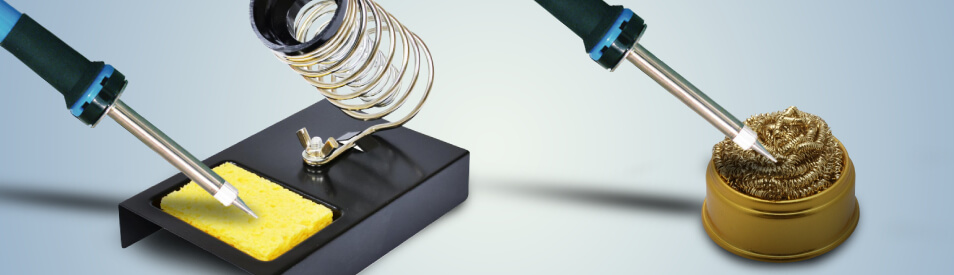

Yellow Sponge |

|||

|

Elenco, Soldering Iron Holder |

The sponge material is porous, thus allowing the water to be held in it. When you rubber hot soldering iron tip on a moist sponge, it will result in the solder dealing at several rates than the soldering tool, thus allowing it to pick off any particles of solder that can be stuck to the soldering iron’s tip. Be sure that the sponge is moist, and not moist with water. |

Pros:

Cons:

|

|

Abrasive Brass Coils |

|||

|

|

You should turn off the soldering iron and let the tip cool down. If the tip was muddied by the previous employee, you will need only this item for cleaning the soldering tool. This waterless method helps to remove solder from the tip fast and easily. |

Pros:

Cons:

|

|

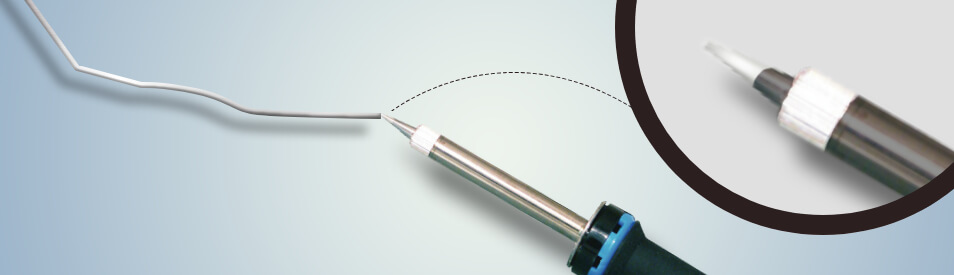

Tip Tinner |

|||

|

|

Tip Tinner is a compressed tablet that consists of lead-free solder and oxide-reducing compounds. This mixture is applied for safe cleaning and re-tinning of high-oxidized soldering iron tips. |

Pros:

Cons:

|

|

Sandpaper |

|||

|

|

Sandpaper has the same function as the abrasive brass coil has; however, it’s not recommended as well, as it may destroy the coating of the soldering iron tip and lead to several damages or issues with soldering. You should remember that the sandpaper fires up at 451F, so be sure that you have unplugged the soldering tool, and let it chill before applying the sandpaper. |

||

How Does The Soldering Tip Get Dirty

Soldering iron tip becomes hot thud oxidizing fast, thus becoming dirty or polluted just being attached with the soldering iron holder.

When the soldering iron tip transfers the heat, it will be greatly reduced when it is coated with oxides and the rest of the burnt flux. It will be impossible not only to provide the heat but also will restrict the solder from moistening or holding on to the tip. Usually, heat transfer passes through the heat bridge that is situated between the soldering iron tip and elements, so the tip that holds off the solder will be useless. The more oxides and other flux are on the tip, the harder the tip will operate, which is why it is important to clean it regularly.

How To Clean Soldering Iron appropriately

Step 1:

Check the temperature of the soldering iron tip, because applying extremely high temperatures may cause fast oxidation of the tip. It is recommended to lower the temperature before you start cleaning the soldering iron tip.

Step 2:

Wipe the iron tip on a moist sponge thus removing oxides faster and reducing the waste. Make a half-circle turn across the sponge to clean all the surfaces of the soldering iron tip. Unplug the soldering iron and let it chill entirely. Pull the soldering iron tip directly into the abrasive brass coils and push back and forth until clean.

Step 3:

Heat the soldering iron tip a little bit. Pull the tip into the tip tinner and you will see some smoke. Wait until the metal melts and leave the tip for 10 seconds and a tip tinner.

You may need to rotate the tip in the tip tinner if the tip is large or the amount of tip tinner is getting low. Pull out the tip and brush it off the sponge or abrasive brass coils to remove the extra solder.

Step 4:

When you finished, tin the tip with an extra solder cover and check whether the toll will accept it. If it does, you perform a proper cleaning, if not - repeat the cleaning operation one more time.

After cleaning the soldering iron tip provides a new covering of solder. Repeat this step a few minutes after, to apply a little soldering to the tip thus preventing the iron tip from getting oxidation.

Helpful Tips For Soldering Iron Tip Care and Maintenance

The soldering iron tip is the most significant element during the operation of the tool. Unless it operates its principle of effective heat transmission to the attachment point, the soldering tool itself will be unstable. Caring for the soldering tip poorly will lead to a problematic soldering process. Soldering tips are tired out over time and regularly need to be replaced. However, by following several unique steps to care for the soldering tip, it will be possible to expand their life. Following the steps below, you will achieve the appropriate soldering iron tip care.

Tip 1

Check the appropriate installation of the soldering tip and make sure that the major soldering element is securely attached. Unless the tip is secured appropriately, it won’t be hot enough to soften the solder.

Tip 2

While you work with flux, prevent a direct attachment with your soldering tool as the acids in the material will corrode the tip of the soldering tool.

Tip 3

When the soldering iron tip provides the optimal temperature for the work, it means that it is installed, cleaned, and cared for appropriately. Poorly cared for or old soldering tools won’t soften the material because of oxidation.