- Show results for

- Share

How Do Ultrasonic Cleaners Work?

Resource Description

Ultrasonic cleaners are the perfect equipment to provide detailed cleaning on nearly every item from jewelry, tools, and carburetors to watches, firearm components, and coins, it is quite tough to find the maximum of what they can clean. Ultrasonic cleaning is a mild and invasive method due to modern technologies that can’t be done correctly at home.

To achieve better consequences utilizing the ultrasonic cleaner it is crucial to understand how to use the device.

What Is Ultrasound Cleaner And How Does It Work?

Ultrasonic cleaning is a cleaning action that applies ultrasound and fluid to clean items. Ultrasonic cleaners are most commonly applied to finish clean fragile components.

Several microscopic vacuum-filled bubbles rapidly boost and downfall when the ultrasonic waves go through the fluid in the ultrasonic cleaner. The ultrasonic waves lead these minuscule bubbles to downfall, that in turn transmits high temperatures and enormous energy into the fluid.

Because this all happens on a small scale and due to the bubble’s expansion and downfall cycle being extremely short, the fluid only becomes mildly warm instead of absurdly hot. The combined impact of the millions of downfall bubbles is what leads to the cleaning impact of ultrasonic cleaning. Grease, rust, flux, and other pollutants break apart and flow into the fluid. This is a very impactful cleaning method with the correct cleaning liquid.

Popular Products

What Are The Pros Of Ultrasonic Cleaning?

The ultrasonic cleaning method has many pros, especially relating to cleaning by hand. Ultrasonic cleaning is y and efficient. There is more pross listed below:

Clean a wide range of pollutants:

There are a few maximums to the pollutants the ultrasonic cleaner can clean and remove. Some examples of pollutants are grease, oil, dirt, dust, rust, pigment, lime, scale, flux, burned carbon, fingerprint oils, and buffing pollutants.

Thorough cleaning

Ultrasonic cleaning removes even the smallest dirt and particles of pollutants. After a while cleaning process with the proper cleaning fluid, items may look new.

Mild

When the cleaning is thorough, it is also mild and doubtful to cause damage which makes ultrasonic cleaners ideal for cleaning jewelry, watch components, or other delicate items.

Clean hard-to-reach spots

The ultrasonic cleaner is not able to clean only revealed surfaces, but also the hard-to-access and even hidden areas which makes it useful for cleaning things like fuel injectors, carburetors, and other complex parts.

Clean multiple items simultaneously

The ultrasonic cleaner is big enough, so you can include additional items to the tank and clean them without additional effort.

Easy to utilize

It doesn’t require so much time or effort to learn how to utilize the ultrasonic cleaner, as everyone can use it.

Time-efficient

When the ultrasonic cleaning cycle can take a while according to the item being cleaned (typically from 2 to 20 minutes), you may clearly set up the equipment and then do another task.

Low maintenance

The ultrasonic cleaner is usually a simple machine and doesn’t require a lot of maintenance.

Cost-efficient

The ultrasonic cleaning is cost-efficient as it is simple to utilize and doesn’t involve much effort.

Safe

There is no risk of cuts or injuries while cleaning drill bits, scalpels, or other sharp items when utilizing the ultrasonic cleaner. Moreover, there is no need to operate with aggressive liquids that are likely hazardous to your health.

What Is Cavitation?

The ultrasonic cleaner harnesses the energy of cavitation to remove germs, particles, or whatever pollutant you are aiming for on any surface that can safely be immersed in biodegradable cleaning liquids.

The ultrasonic cleaner cleans intricate and fragile instruments, such as dental or laboratory tools, effortlessly, as they can disperse and dissolve samples as well as immediately remove liquids.

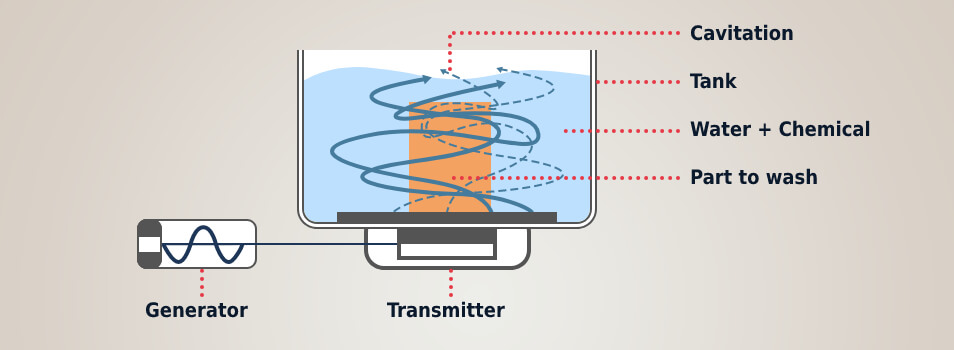

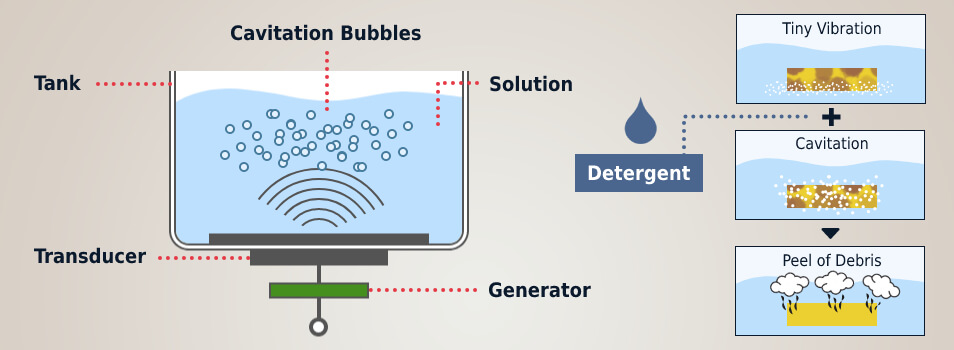

Cavitation is the process when the static pressure of the liquid is reduced to the point below the liquid’s vapor pressure, leading to the formation of small, vapor-filled cavities in the liquid. The ultrasonic cavitation is produced in the ultrasonic cleaning tank, by ultrasonic energy-generated ultrasonic transducers attached to the bottom of the tank.

The ultrasonic cleaning relies on a spectrum of sound frequencies that are inaudible to the person’s ear. Ultrasonic frequencies range from 20.000 to 100.000 cycles per second and lower or higher frequencies have various impacts and may be applied for special applications.

Some tips show how they make items and parts sparkle:

- Polluted items are put into the cleaning tank of liquid (the cleaning liquid);

- The ultrasonic cleaner produces the sound wave series into the specialized liquid by utilizing an immersible ultrasonic transducer, that shakes up the liquids with sound waves with a high frequency;

- Transducers operate to compress and boost the fluid, creating microscopic cavitation bubbles by squeezing tightly and then separating quickly. The process is called cavitation, a busting action that causes a partial vacuum, and generates extremely high exit velocities for each bubble;

- All these actions happen incredibly quickly, with surrounding liquids absorbing each bubble’s heat nearly instantly;

- This will give you an accurate, easy-to-utilize system for cleaning any part of an item safely, gently, and especially targeted at the pollutants, germs, oils, and other rubble the industry generates.

- As a consequence, the simple process of ultrasonic cleaning is usually impactful and productive when cleaning assorted components of items.

Cleaning Liquids And Fluids

One of the reasons, why it is required to include cleaning liquids in the ultrasonic cleaner, is that the surface tension resists cavitation. That is why a surfactant, also known as a wetting agent, should be included. A surfactant is a chemical liquid that lowers the surface tension of the fluid and reduces the tendency of molecules to stick to each other. The ultrasonic cleaning liquid does exactly this but also has other ways of optimizing the ultrasonic cleaning operation.

The ultrasonic cleaning liquids develop the cleaning operation in several ways:

Decrease water surface tension to boost the cavitation

The ultrasonic cleaning liquid includes a surfactant (a wetting agent) that reduces surface tension in the fluid. This offers the creation of more microscopic bubbles. the more bubbles the better and faster the cleaning.

Emulsify And Disperse Oils

The surfactant provides oil molecules to mix with water molecules, offering them to be dispersed into the liquid more easily.

Prevent Corrosion

Several ultrasonic cleaning liquids include additives (corrosion inhibitors) that prevent rust and other corrosion.

So, which cleaning liquid should you utilize for the ultrasonic cleaner? There are plenty of ultrasonic cleaning liquids accessible. A few most common ones are acidic (low pH, alkaline (high pH, neutral, high caustic, and enzymatic liquids). These liquids are all good at bonding to and removing specific pollutants.

Popular Products

Important Tips For Proper Use Of Ultrasonic Cleaner

There are various factors that impact how long the part or item should be placed in the ultrasonic cleaner:

- Various pollutants demand various cleaning times. Loose pollutants such as dust, metal shavings, and soot come off clearly due to the molecules not interacting with the surface of the item.

- Grease, oil, and wax take more time to remove as their molecules produce bonds with metals and plastics and usually produce bonds with each other. These bonds should be broken by the forces of the imploding bubbles before the pollutants come off. Carbon deposits, rust, and other oxidation are the toughest to remove and these pollutants demand the most cleaning time.

- The more dirt the more time it takes to be removed. Pre-rinsing of the parts offers speeding up the operation to remove the bulk of the pollutant. You should note that pollutants stick to materials assertedly. The cleaning liquid that is correct for the material being cleaned will provide a better job than other, more generic liquids.

- A batch of fresh cleaning liquids without particles and rubble floating around in it will perform better than a batch that has already been applied multiple times. For various applications, the cleaning liquid in the ultrasonic cleaner is required to be warmed up. Each cleaning liquid should be warmed up to its own optimal working temperature, usually between 122- 149*F (50-65*C).

- You need to have more energy (per unit of volume) from the ultrasonic cleaner for cleaning dirt and other large particles. It is required to utilize less energy on fine particles on lightly contaminated items.

- The lower the ultrasound frequency, the larger bubbles with more energy will operate well when cleaning large surfaces. The higher the frequency, the finer and fewer energy bubbles that operate well for cleaning small intricate surfaces.